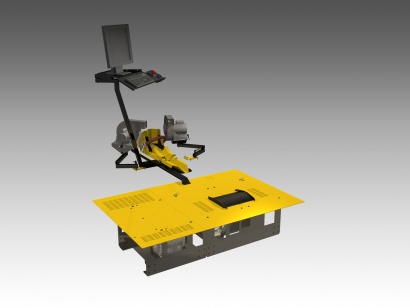

Dynojet 250ip Dynamometer Pit Model

The 250i Load Control System was developed through years of experience with over 6,000 dynamometer installations world wide. The design is easy to operate and provide the function of steady state load control. Dynojet's Load Control System uses the latest in Eddy Current Power Absorption technology, which combines with our easy to use software, so any technician can get repeatable, consistent results. The Load Control software provides the technician with the ability to control vehicle RPM or Speed at any throttle opening. Through our exclusive closed-loop software design, the vehicle is automatically held at your pre-determined setting.

• Measures up to 750hp and 200mph

• NEW PowerCore Software suite with WinPEP 8 (PC, monitor, printer, etc. not included)

• NEW DynoWare RT dynamometer electronics and hardware

• 2 channels available for Automatic Conditions Measurement (absolute pressure, air temp, humidity) 1 sensor included

• 4 Analog Input Channels for 0-5v sensors (sensors and cables not included)

• 14 expansion ports for DynoWare RT accessories and DJ-CAN devices (such as Power Commander, Power Vision, Autotune, etc.)

• Integrated control panel stand with console

• Ignition wire inductive tachometer pickup leads

• Power carriage for button operated wheelbase adjustment

• Pit Covers

• Compact design allows for smaller pit size

• Front wheel lock

• Starter system to spin roller (12V, battery not included)

• Installation and operation manuals

• One year replacement parts warranty

• Free technical support

• Eddy Current Load Absorption Unit (250 series only)

Back